Wet Belt Servicing

Expert Wet Belt Replacement for UK Cars & Light Commercial Vehicles

Equipped with specialist tools and deep technical expertise, GB Transport Services offers professional wet belt diagnostics, servicing, and replacements you can trust.

Wet Belts and Why Do They Matter?

Wet belts (also known as belt-in-oil timing belts) are increasingly common in modern petrol and diesel engines. Designed to run inside the engine in oil for reduced noise and wear, they require careful maintenance and timely replacement. If left unchecked, a degraded wet belt can cause severe internal engine damage, MOT failure, or complete breakdown.

Book nowWe provide a full diagnostic and replacement service using the correct OEM-spec tools and procedures.

From preventative care to restorative dentistry, our team is dedicated to providing the best possible dental care for you. Enthusiastically supply parallel convergence after high standards in e-markets. Progressively administrate fully researched partnerships and market positioning web-readiness. Credibly scale an expanded.

-

Wet Belt Inspection & Diagnosis

Using advanced tools to identify wear, degradation, or noise related to wet belt systems.

-

Full Wet Belt Replacement

Complete belt replacement using manufacturer-approved procedures and high-quality components.

-

Oil & Filter Replacement

Includes oil change and filtration to ensure the new belt operates in optimal conditions.

-

Warranty-Safe Servicing

All work completed to manufacturers' specifications, protecting your vehicle's warranty and long-term performance.

Wet belt service interval (often as early as 60,000 miles or 6 years).

- Cost-saving: early replacement vs. engine rebuild

- Maintain manufacturers warrenty

- latest diagnostic tools and replacement kits

Without Timely Wet Belt Replacement

Wet belts—also known as belt-in-oil timing systems—are a known weak point in many modern engines, particularly if they aren't serviced

at the correct intervals. In this gallery, we share real-life examples of the kind of damage we regularly see in our workshop when wet belts begin to fail.

From missing belt teeth and degraded rubber debris contaminating the oil system, to blocked oil pickups and severe top-end engine damage from oil

starvation—these images show just how critical it is to inspect and replace wet belts before failure occurs.

If you suspect a wet belt issue, don't delay. Early diagnosis and intervention can prevent catastrophic engine failure and save you thousands in repair costs.

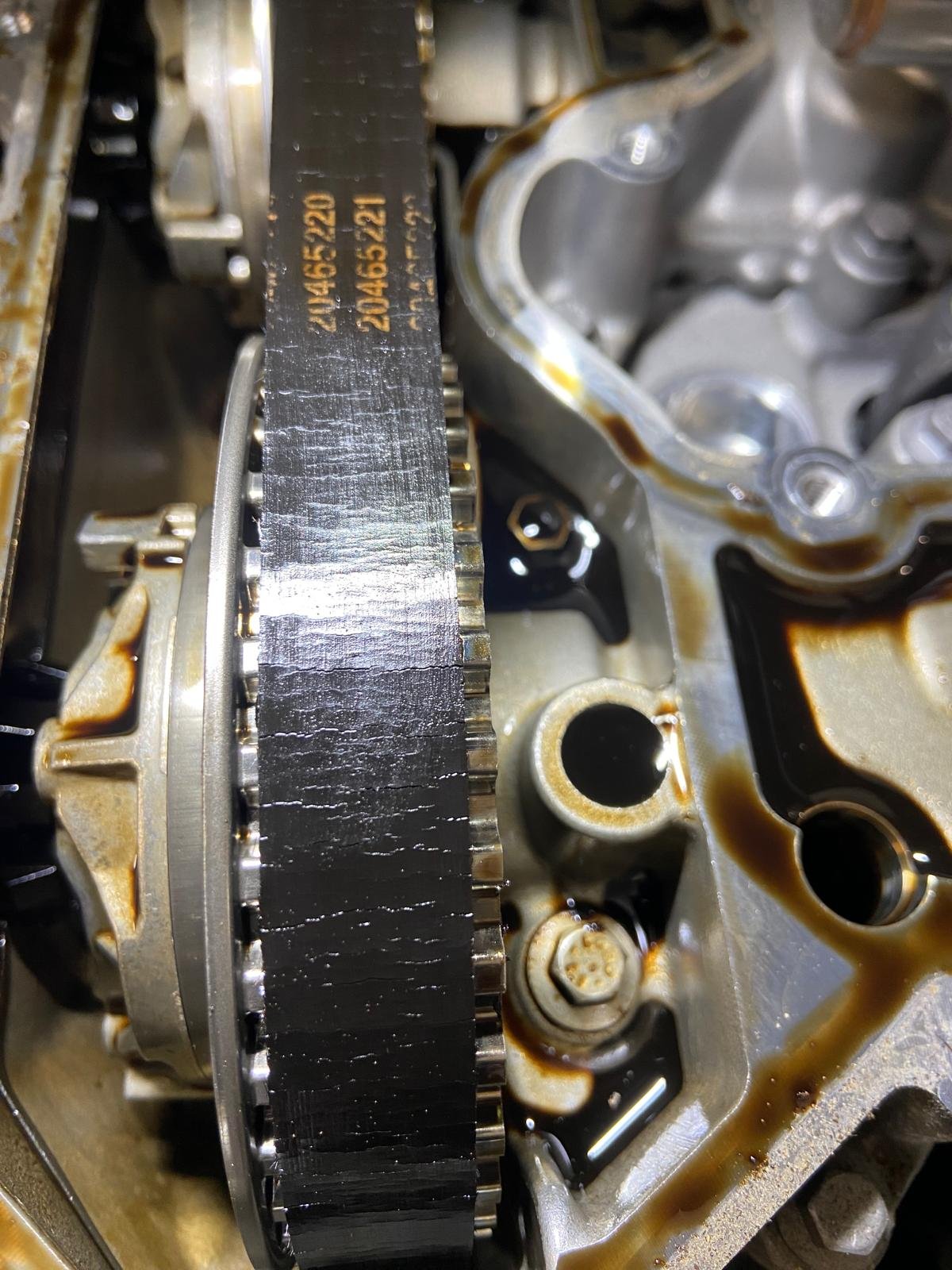

Wet belt degrodation

Rubber fragments from a deteriorating wet belt found in the engine sump — a clear sign of internal belt breakdown.

Wet belt degrodation

Contaminated oil thickened with sludge from belt particles, reducing flow and increasing engine wear risk.

Wet belt degrodation

Portions of the wet belt teeth have broken away, risking engine timing failure and catastrophic internal damage.

Wet belt degrodation

Severe damage to valve gear and camshaft due to prolonged oil starvation — a preventable failure with early wet belt replacement.

Wet belt degrodation

Close-up showing fine rubber particles choking the oil strainer mesh — reducing oil pressure and flow..

Wet belt degrodation

Severe damage to valve gear and camshaft due to prolonged oil starvation — a preventable failure with early wet belt replacement.